RunTek Flexible PCB manufacturing

A flexible PCB is a patterned arrangement of printed circuit and components that makes use of flexible base material with or without flexible cover layer. The flexible electronic assemblies can be fabricated with the same components as the rigid printed circuit board, however, allowing the board to meet the demands of necessary shapes during its applications.

RunTek ELECTRONICS Flexible PCB Capabilities

| No. | Item | Process Capability Parameter |

|---|---|---|

| 1 | PCB Type | Flexible PCB |

| 2 | Layer Count | 1-6 Layers |

| 3 | Material | Polyimide Flex |

| 4 | Board Type | Single Piece/In Panel |

| 5 | Board Thickness | 0.08mm-0.15mm |

| 6 | Min Tracing/Spacing | ≥0.06mm |

| 7 | Min Hole Size | ≥0.15mm/0.35mm/No Drill |

| 8 | Coverlay | Yellow, White, Black, None |

| 9 | Silkscreen | White, Black, None |

| 10 | Surface Finish | ENIG, OSP, Immersion Tin, Chemical Silver |

| 11 | Finished Copper | 2 oz. Cu(70μm) |

| 12 | Quality Grade | Standard IPC 2 |

| 13 | Lead Time | 5-7 days |

Flexible PCB (FPC) STACK UP

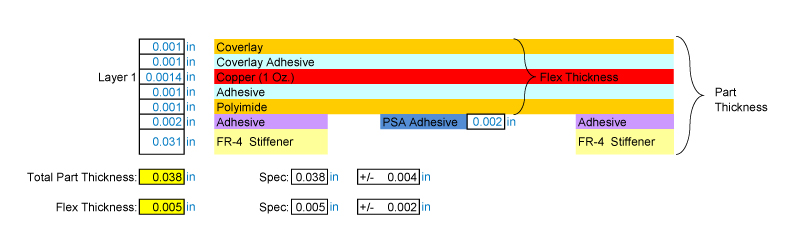

1 Layer Flex PCB with Optional FR-4 Stiffeners and PSA

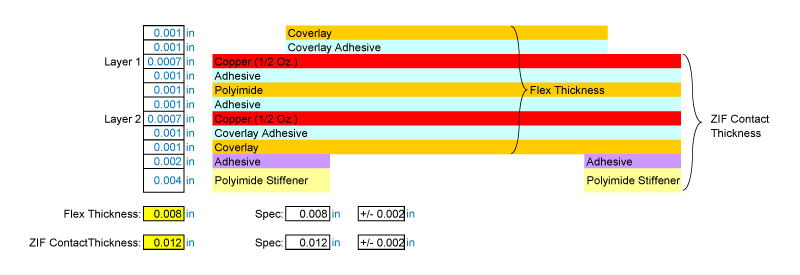

2 Layer Flex Circuit with ZIF Contact Fingers

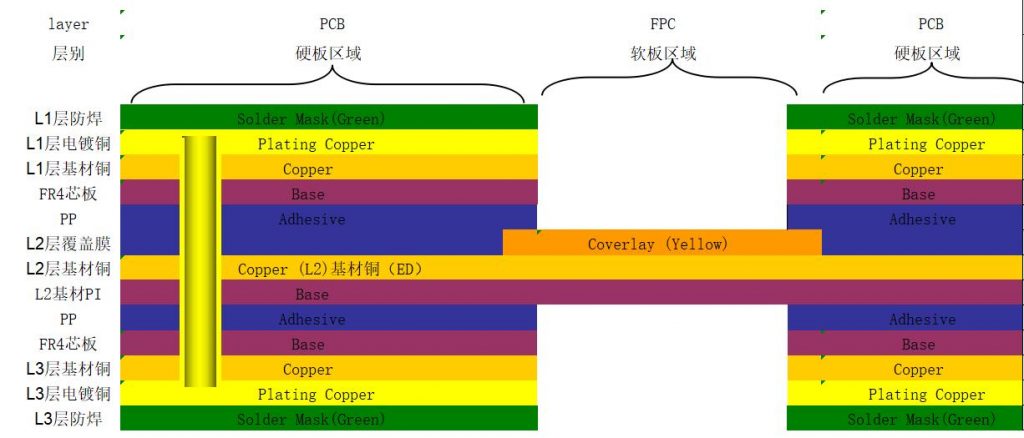

Multi-Layers Flexible PCB(FPC) laminate the Layers as above

RunTek ELECTRONICS Rigid-flex PCB capabilities

| No. | Item | Process Capability Parameter |

|---|---|---|

| 1 | PCB Type | Rigid-flex Board |

| 2 | Layer Count | 2 layers, 4 layers, 6 layers, 8 layers |

| 3 | Board Type | Single Piece/In Panel |

| 4 | Material | Polyimide Flex+FR4 |

| 5 | Board Thickness | 0.4-3.2mm |

| 6 | Min Tracing/Spacing | 4mil/4mil, 5mil/5mil, 6mil/6mil |

| 7 | Min Hole Size | 0.15mm, 0.2mm, 0.25mm, 0.3mm, None |

| 8 | Immersion Gold, OSP, Immersion Silver | Immersion Gold, OSP, Immersion Silver |

| 9 | Gold Fingers | Available |

| 10 | Via Process | Tenting Vias, Plugged Vias, Vias not Covered |

Flex Part

No. | Item | Process Capability Parameter |

|---|---|---|

| 1 | Layer Count | 1, 2 Layers |

| 2 | FPC Thickness | 0.13mm, 0.15mm, 0.18mm, 0.2mm |

| 3 | Coverlay | Yellow, White, Black, None |

| 4 | Silkscreen | White, Black, None |

| 5 | Finished Copper | 0.5oz Cu, 1oz Cu, 1.5oz Cu |

Rigid Part

| No. | Item | Process Capability Parameter |

|---|---|---|

| 1 | Solder Mask | Green, Red, Yellow, Blue, White, Purple, Black, Matte Black, Matte Green, None |

| 2 | Silkscreen | White, Black, None |

| 3 | Finished Copper | 1oz Cu, 2oz Cu, 3oz Cu, 4oz Cu |

| 4 | Additional Options | Half-cut/Castellated Holes, Impendence Control |

Rigid-Flex PCB STACK UP

1+1+1 layers Rigid-Flex PCB stack up

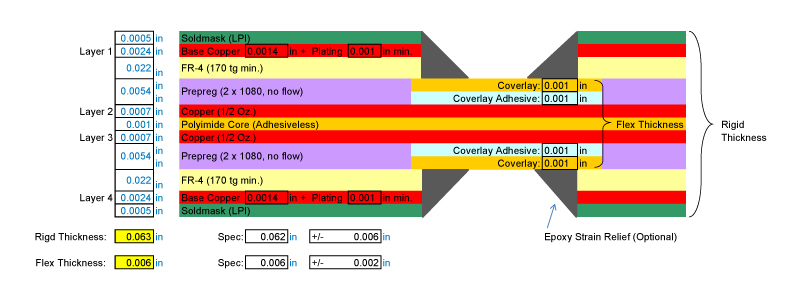

4 Layer Rigid-Flex PCB (2 Flex Layers)

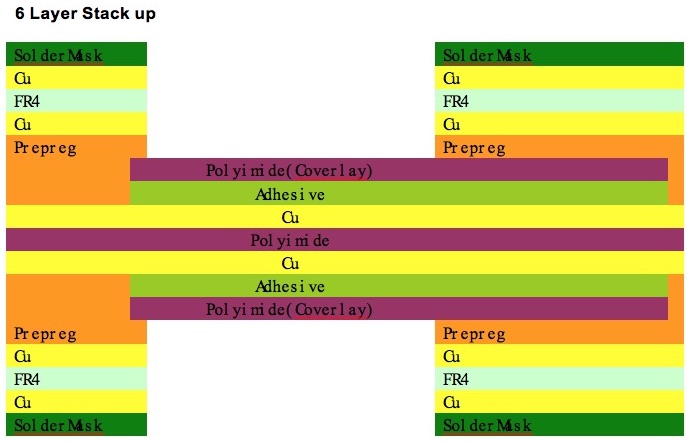

6 layer Rigid-Flex PCB stack up

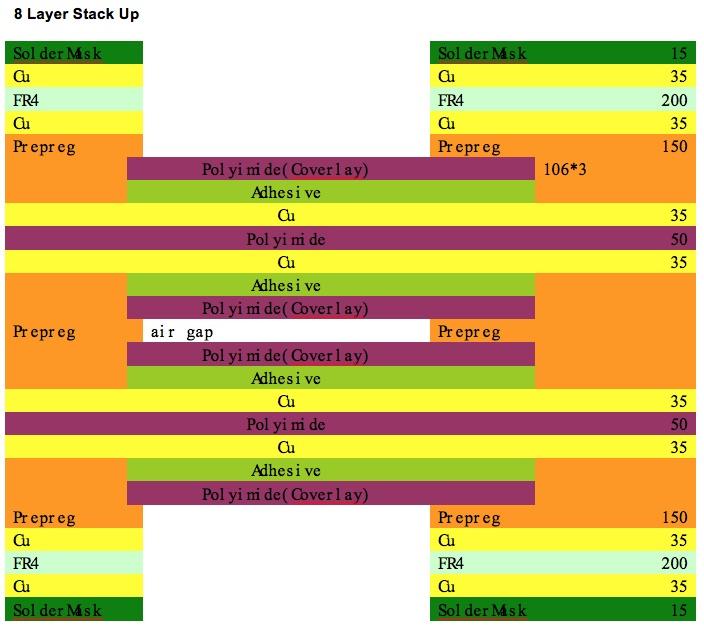

8 layers Rigid-Flex PCB stack up

Choose RunTek ELECTRONICS for your Flexible and Rigid-Flex PCBs

Flexible PCBs are beginning to replace rigid circuit boards due to their versatility thanks to its preferable advantages, such as: flexibility, connectivity, reduced weight, durability, resistant, etc. Its applications include three-dimensional packaging geometry, shock and vibration resistance, durable thin and lightweight products, wiring solutions that where rigid PCB cannot, and miniaturized versions of existing technologies, etc.

All of the electrical and mechanical connections are internally contained within the rigid-flex PCB, providing the electronics designer with much improved service reliability and electrical performance. Its applications include Telecommunication equipment, Research institute, Computer, Automotive, Medical treatment, Digital data, etc.

If you are majoring in the above areas and looking for Flexible or Rigid-Flex PCB for your project, Submit a quote for your specific Flexible PCB or Rigid-Flex PCB requirements or Contact us if you would like to arrange a tour of our production facility. Our email address: [email protected] . Skype ID: [email protected] . WhatsApp: +8613392412348. And our sales and engineer team will response to you once receive your quotation!