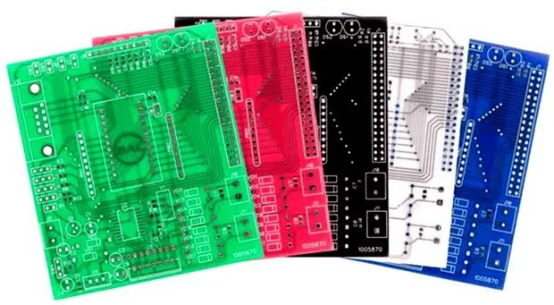

1.PCB board color

Even for some people who don’t know what a PCB is, they generally know what a PCB looks like. They at least seem to have a traditional style, which is its green color. This green is actually the transparent color of the solder mask glass paint. Although the name of the solder mask is solder mask, its main function is to protect the covered circuit from moisture and dust.

As for why the solder mask is green, the main reason is that green is the military protection standard. The PCB in the military equipment first used the solder mask to protect the reliability of the circuit in the field. Green is the natural protection color in the military. Some people think that the color of the epoxy resin used in the original solder mask paint is green, so it is still used today.

Now the colors of the solder mask are various, including black, red, yellow and so on. After all, green is not an industry standard.

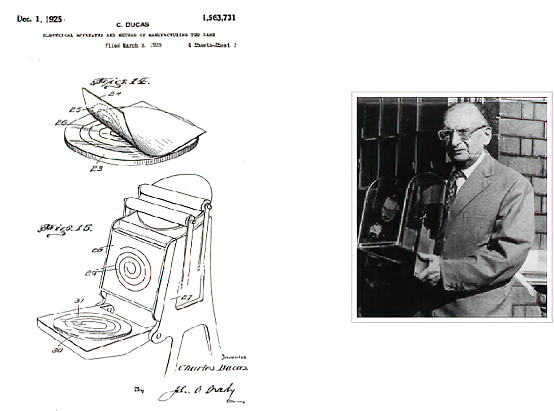

2.Who invented the PCB

The earliest printed circuit boards need to be traced to the Austrian engineer Charles Ducas in 1920, who proposed the concept of using ink to conduct electricity (printing brass wires on the bottom plate). He used electroplating technology to produce wires directly on the surface of the insulator, and produced a prototype of the PCB.

The metal wires on circuit boards were originally brass, an alloy of copper and zinc. This disruptive invention eliminates the complicated wiring process of electronic circuits and ensures the reliability of circuit performance. This process did not enter the practical application stage until the end of the Second World War.

Printed circuit board patents and Charles Ducas

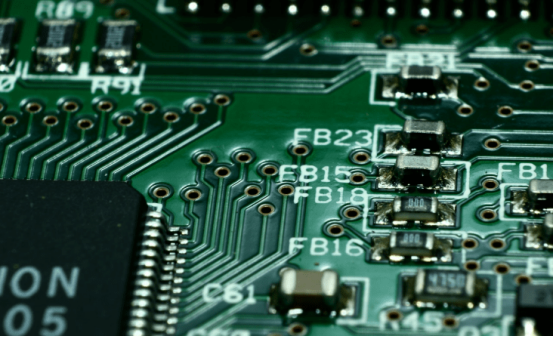

3.White mark

There are still a lot of white marks on the green circuit boards. For many years, people did not understand why these white printed marks were called “silk screen layers.” They are mainly used to identify the information of the components on the circuit board and other content related to the circuit board.

This information was first printed on the circuit board by screen printing, so it is called the screen layer, and now it is done using a special inkjet printer. This information can help circuit engineers to check whether there are faults in the circuit board.

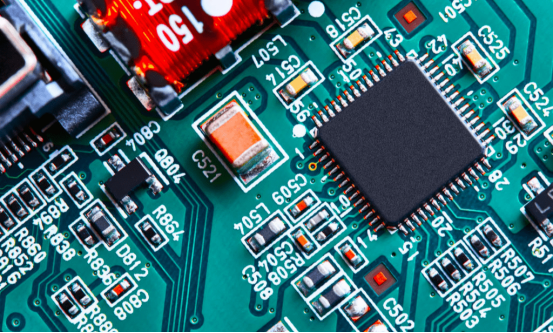

4.Components

The function of the circuit board is mainly completed by effectively connecting the components according to the schematic diagram. Each component has its unique function. Even two devices that are closely adjacent on the circuit board can be very different. The types of devices basically include resistors, diodes, transistors, capacitors, relays, batteries, transformers, and many others (such as fuses, inductors, potentiometers, etc.).

5.PCB is everywhere

It is no exaggeration to say that PCBs are everywhere. From computers to digital clocks, from microwave ovens to televisions and stereo systems. As long as it is electronic items and equipment, there is more than 99% of the possibility that PCBs are included. So we may take it for granted that if there is no PCB, any electronic equipment may not be able to operate.

6.NASA

In many projects of the National Aeronautics and Space Administration (NASA), some groundbreaking technologies have been used. Among them, in the 1960s, NASA used PCB on the Apollo 11 rocket. This is because of PCB-based electronics. The equipment is light in weight and consumes little power. That was the greatest moment of mankind, sending an astronaut to the moon for the first time. Among them is the credit of PCB.

7.Surface package soldering technology

Surface mount soldering technology has modernized the PCB. Compared with the previous jack mounting method, this surface mounting soldering technology first uses special glue to paste the device on the PCB, and then electrically connects the device with the circuit board through a special reflow soldering.

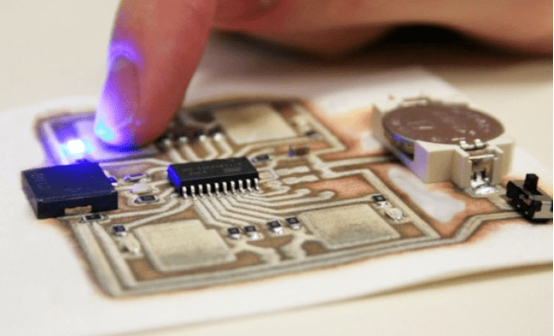

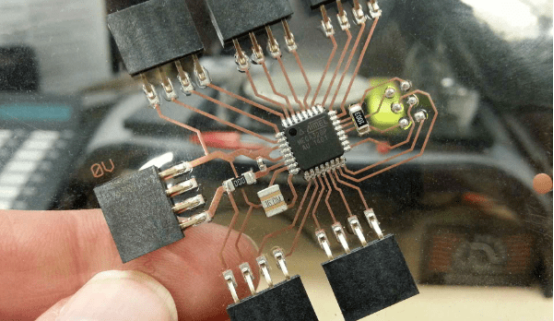

8.Rapid Prototyping PCB

In the process of partial experiment of the circuit, you can use breadboard, hole board and other general circuit boards to test. With the increase of surface packaging components, new rapid PCB molding technologies have emerged, such as thermal transfer PCBs, 3D printed multilayer circuit boards, and so on.

3D printed circuit board

9.Flexible PCB

PCBs are not all straight and hard, and there are many flexible PCBs that work in many compact electronic devices. They often constitute application circuits in many movable joints, or constitute multilayer three-dimensional circuits.

10.The largest PCB in the world

The largest PCB in the world comes from this flexible multilayer circuit board used in unmanned solar-powered aircraft from Johnson Electronics in the United Kingdom. It is about 28 meters long. The circuit board made of soft polyimide as the base has better heat dissipation and higher conductivity. Such a long circuit board is made by etching in sections through a special production process.

If you have any PCB demands, please feel free to contact us.

Email:[email protected]

Skype:[email protected]

Telephone number:+86 133 9241 2348

Whatsapp: +86 133 9241 2348