What is rigid flex circuitry?

Traditional rigid circuit boards are valued for their simple manufacturing design and easy-to-cut angles, which makes them less expensive to produce at scale. Today’s design technology, however, often calls for more flexible circuitry that is able to adapt to varied form factors. Smaller, less obtrusive devices call for more compact processing solutions and because of that, first generation circuit boards do not make the cut.

Flexible circuits, though, given their form-adaptive properties are able to bend, fold, and twist. Because of this, flexible circuits can also be made smaller; this enables them to fit in places where more obtrusive and heavier weight rigid boards would be impractical. In addition, flexible circuits can reduce the need for wiring by up to 75% and can also reduce the cost of electrical connections by 70%. Given this overall reduction in weight, cost, and pliability, flexible circuits have broad appeal for application into medical device technology such as prosthetics, implanted and external medical devices, and lab equipment.

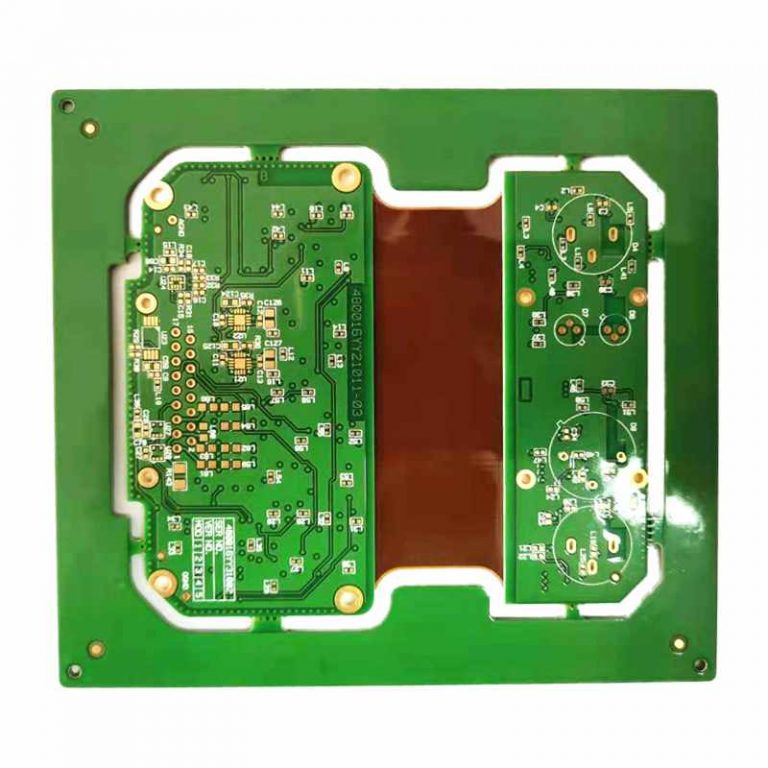

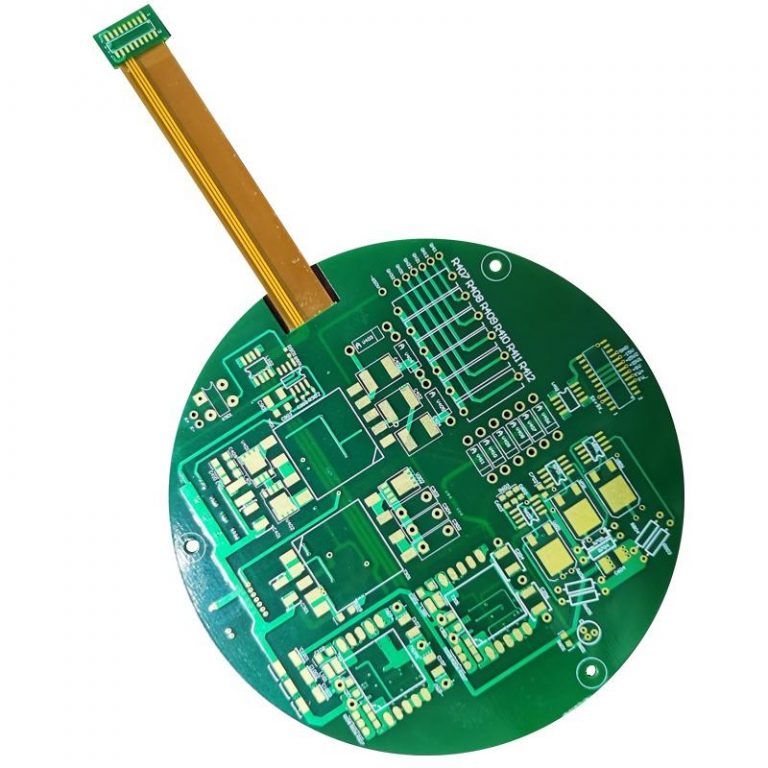

While the benefits of flexible circuitry are clear from a design, production, and use standpoint, traditional rigid boards still do offer value in durability and economy. For some use cases, designers opt to use rigid flex technology, which combines the two types of circuitry in a hybrid form. Rigid flex circuits utilize the favorable attributes of these two main types of circuit boards to offer more support (rigidity) when needed in particular designs as well as the option for flexibility when preferred (around corners or angles, for instance).

There are two main structural assemblies for rigid flex circuitry. The first is static — otherwise known as flex-to-fit or flex-to-install where the flex circuit is only needed to install and fit the circuit itself. The second type of structural application is known as a dynamic flexing application; this is when the flex circuit area is dynamically flexed beyond a traditional install.

Rigid flex circuits in prosthetics

Engineers at Stanford University have created a skin facsimile that is able to detect pressure and other sensory sensations. Researchers are hopeful that this “plastic skin” might eventually be used in prosthetics to allow users to distinguish between different textures, degrees of pressure, as well as temperatures. The surface area uses a hybrid system with a top layer that senses (or feels) and a bottom layer that houses a circuit which transports electrical signals that convert them into stimuli that mimic biological response. Though this project is still in its experimental phase, researchers hope to bring this proof-of-concept to real-world functionality so it can ultimately serve as a form of artificial skin for both prosthetics and others in need of skin grafting due to severe burn or injury.

Rigid flex circuits in implantable medical devices

More advanced medical devices such as cochlear implants or implants for damaged retinas require that powerful processing be contained within a flexible form factor. Researchers from the Korea Advanced Institute of Science and Technology have now developed a method of placing powerful silicon circuits onto flexible material and then encasing them in durable polymers that are biocompatible with the physiological environment of prostheses.

For implantable devices like cochlear or retinal implants or pacemakers where reliability and biocompatibility are essential, these hybrid circuits can leverage the benefits of being compact and lightweight while harnessing the durability and longevity of rigid board structures to encase powerful computing.

Rigid flex circuits in surgical equipment and patient monitoring devices

In addition to using rigid flex circuits in surgical equipment like cauterizing scissors or electronic saws, rigid flex technology is also utilized in wearable technologies used for patient monitoring. These products include devices that monitor blood pressure, heart rate, pulse, and other vital signs. Rigid flex circuits can also provide processing solutions in other external patient devices such as insulin pumps, portable defibrillators, CPAP machines for patients with sleep apnea. Using a combination of rigid and flexible components bonded together in one structure allows the circuits of the device to be even smaller yet still maintain their durability. In addition, the structure of rigid flex technology allows for digital and analog circuits to be separated.

Conclusion

Rigid flex circuits utilize the strengths of both types of circuit boards and integrate them together in a way that is complementary and full of potential for application in future product development. The benefits that rigid flex circuits bring include reliability of connection, fewer parts, and flexible design options, making them a ready partner in tomorrow’s innovation.