The main reason for the reserved board edge in the production of Rigid-flex PCB is that the SMT placement machine track is used to clamp the circuit board and flow through the placement machine, so components that are too close to the edge of the track are sucked by the SMT placement machine. When the components are drawn and mounted on the circuit board, the phenomenon of collision occurs and the production cannot be completed. Therefore, in the production process of the Rigid-flex PCB, in order to consider the subsequent patches and plug-ins, the board edge is generally added. So, what are the benefits of the reserved board edge in the production of Rigid-flex PCBs?

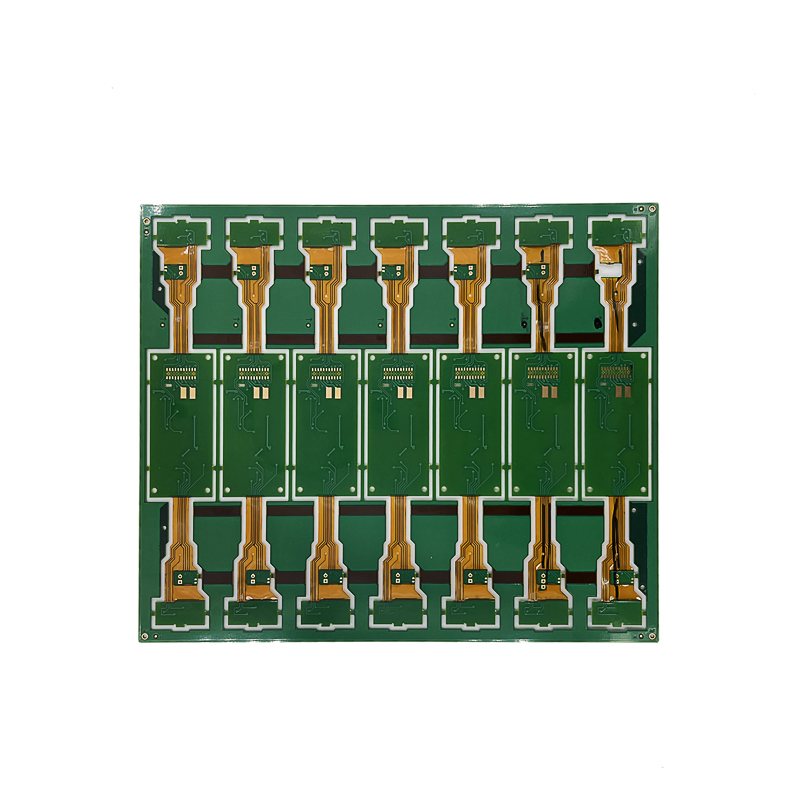

The reserved board edge is to assist the SMD plug-in welding and the added part of the board on both sides or four sides of the Rigid-flex PCB. It is mainly for auxiliary production and is not part of the flex-rigid board. The production is completed on the Rigid-flex PCB A. can be removed later.

The reserved board edge for Rigid-flex PCB production will consume more plates and increase the production cost of Rigid-flex PCB. Therefore, when designing the Rigid-flex PCB board edge, it is necessary to balance economy and manufacturability. For some special circuit boards, the flex-rigid board that originally had 2 process sides or 4 process sides can be greatly simplified by assembling the Rigid-flex PCB. Smt patch processing When designing the paneling method, it is necessary to fully consider the track width of the SMT placement machine. For panels exceeding the width of 350mm, it is necessary to communicate with the process engineer of the SMT supplier.

The flatness of the edge of the flexible and rigid board production process is also an important part of the printed circuit board production. When removing the production board edge of the Rigid-flex PCB, it is necessary to ensure that the board edge is flat, especially for circuit boards that require extremely high assembly accuracy. Any uneven burrs will cause the installation holes to be offset, which will bring great harm to subsequent assembly. big trouble.

If you have any PCB demands, please feel free to contact us.

Email:[email protected]

Skype:[email protected]

Telephone number:+86 133 9241 2348

Whatsapp: +86 133 9241 2348