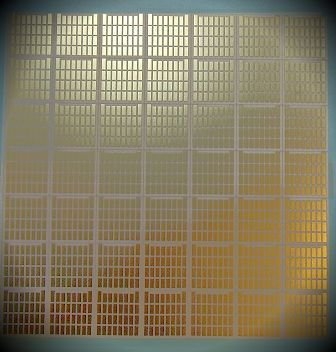

What is a ceramic PCB

Ceramic PCB refers to a special process board in which copper foil is directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate surface (single-sided or double-sided) at high temperature. The made ultra-thin composite substrate has excellent electrical insulation performance, high thermal conductivity, excellent solderability and high adhesion strength, and can be etched into various patterns like a PCB board, and has a large current carrying capacity. ability. Therefore, ceramic substrates have become the basic material for high-power power electronic circuit structure technology and interconnection technology.

Ceramic PCB characteristics

- Strong mechanical stress, stable shape; high strength, high thermal conductivity, high insulation; strong bonding force, anti-corrosion.

- Excellent thermal cycle performance, the number of cycles is up to 50,000 times, and the reliability is high.

- The structure of various patterns can be etched like PCB board (or IMS substrate); it is pollution-free and pollution-free.

- The operating temperature is wide -55℃~850℃; the thermal expansion coefficient is close to silicon, which simplifies the production process of power modules.

Advantages of ceramic PCB

- The thermal expansion coefficient of the ceramic substrate is close to that of the silicon chip, which can save transition layer Mo slices, save labor, save materials, and reduce costs;

- Reduce solder layer, reduce thermal resistance, reduce voids, and increase yield;

- The 0.3mm thick copper foil line width is only 10% of the ordinary printed circuit board under the same current carrying capacity;

- Excellent thermal conductivity, so that the chip package is very compact, so that the power density is greatly improved, and the reliability of the system and the device is improved;

- Ultra-thin (0.25mm) ceramic substrate can replace BeO without environmental toxicity issues;

- Large current carrying capacity, 100A current continuously passes through 1mm wide and 0.3mm thick copper body, and the temperature rise is about 17℃; 100A current continuously passes through 2mm wide and 0.3mm thick copper body, and the temperature rise is only about 5℃;

- Low thermal resistance, the thermal resistance of a 10×10mm ceramic substrate is 0.31K/W for a 0.63mm thick ceramic substrate, the thermal resistance of a 0.38mm thick ceramic substrate is 0.19K/W, and a 0.25mm thick ceramic substrate The thermal resistance is 0.14K/W.

- High insulation withstand voltage to ensure personal safety and equipment protection.

- New packaging and assembly methods can be realized, so that the product is highly integrated and the size is reduced.

Application of ceramic PCB

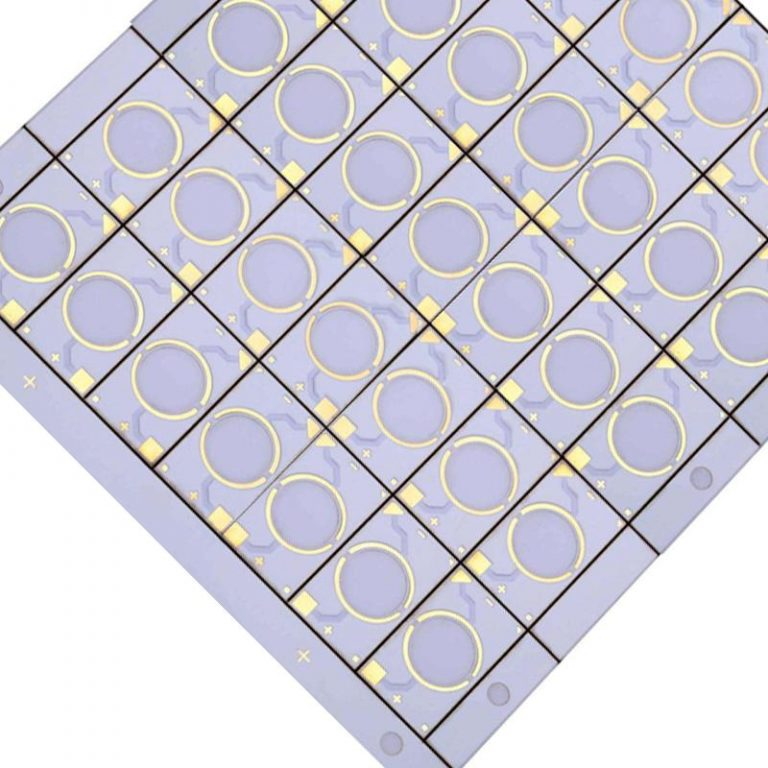

The application of ceramic PCB in the chip

In LEDs, ceramic substrates are often used to make chips to achieve better thermal conductivity. In addition, ceramic PCBs are often used to make ceramic chips in the following electronic devices:

◆High-power power semiconductor module.

◆Semiconductor refrigerator, electronic heater; power control circuit, power mixing circuit.

◆Intelligent power components; high-frequency switching power supplies, solid state relays.

◆Automotive electronics, aerospace and military electronic components.

◆Solar panel components; telecommunications dedicated exchanges, receiving systems; industrial electronics such as lasers.

Application of ceramic PCB in third-generation semiconductors

Mainstream power devices represented by MOSFETs, IGBTs, transistors, etc. occupy a place in their respective frequency range and power supply range. Due to the comprehensive and excellent performance of IGBT, it has replaced GTR as inverter, UPS, frequency converter, motor drive, high-power switching power supply, especially the mainstream devices in power electronic devices such as electric vehicles and high-speed rails.

Application of alumina ceramic PCB in the field of electronic power

In the field of power electronics, such as power switching power supplies, electric drives, etc., dielectric ceramic substrates are required to achieve better thermal conductivity and prevent current burnout and short-circuit.

Application of alumina ceramic co-fired plate in lithium battery industry

With the recommendation of artificial intelligence and environmental protection, the automotive industry has also introduced electric cars, mainly through battery storage. Lithium batteries made of ceramic substrates can achieve better current and heat dissipation functions, and promote the market demand for new energy vehicles.

Application of ceramic PCB in integrated circuits

Small-size ceramic PCB chips (less than 3mm*3mm) can also be packaged with small-size integrated circuits through technology, so the application of integrated circuits is also increasing; after all, the development of integrated circuits has features such as precision and miniaturization.

If you have any PCB demands, please feel free to contact us.

Email:[email protected]

Skype:[email protected]

Telephone number:+86 133 9241 2348

Whatsapp: +86 133 9241 2348