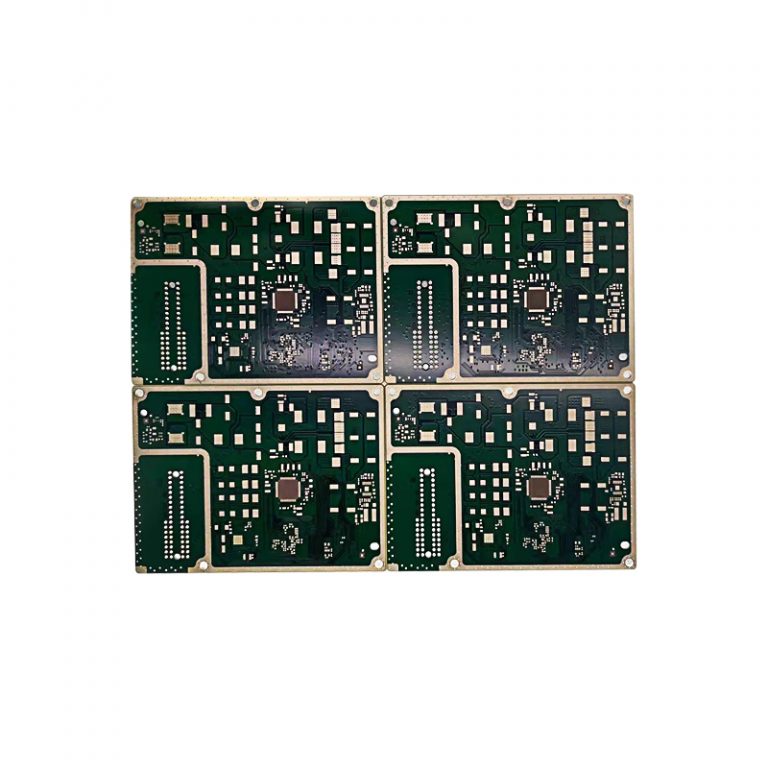

High frequency circuit boards

The increasing complexity of electronic components and switches continually requires faster signal flow rates, and thus higher transmission frequencies. Because of short pulse rise times in electronic components, it has also become necessary for high frequency (HF) technology to view conductor widths as an electronic component.

Depending on various parameters, HF signals are reflected on circuit board, meaning that the impedance (dynamic resistance) varies with respect to the sending component. To prevent such capacitive effects, all parameters must be exactly specified, and implemented with the highest level of process control.

Critical for the impedances in high frequency circuit boards are principally the conductor trace geometry, the layer buildup, and the dielectric constant (εr) of the materials used.

BETON PCBs factory provides you with know-how, all popular materials and qualified manufacturing processes – reliably even for complex requirements.

Design of HF circuit boards

BETON ELECTRONICS supports you starting immediately in the design phase. We help you to find appropriate substrates, dimensioning the conductor width and spacing, as well as with calculating the impedances.

Our offer for HF circuit boards:

HF-material (low-loss), e.g. PTFE substrate

Impedance controlled multi-layers

Sandwich buildup for material combinations

Microvias strating from 75µm

Controlled production line / with comprehensive test certificate, as needed

Backdrill

Materials used for HF circuit boards

High-frequency boards, e.g. for wireless applications and data rates in the upper GHz range have special demands on the material used:

- Adapted permittivity

- Low attenuation for efficient signal transmission

- Homogeneous construction with low tolerances in insulation thickness and dielectric constant

For many applications, it is sufficient to use FR4 material with an appropriate layer buildup. In addition, we process high-frequency materials with improved dielectric properties. These have a very low loss factor, a low dielectric constant, and are primarily temperature and frequency independent.

Additional favourable properties are high glass transition temperature, an excellent thermal durability, and very low hydrophilic rate.

We use (among others) Rogers or PTFE materials (for example, Teflon from DuPont) for impedance controlled high frequency circuit boards. Sandwich buildups for material combinations are also possible.

Impedance Check

The impedance defined by the customer is tested by our CAM station engineers on manufacturability. Depending on the layer buildup, the PCB layout and the customer’s requested impedances a calculation model is chosen. The result is any required modification of the layer build up and the necessary adjustments to the relevant conductor geometries.

Please also refer to our pages for impedance control of printed circuit boards.

After the manufacture of high frequency circuit boards, the impedance are checked (with a precision of up to 5%), and the detailed results are recorded exactly in a test protocol.

Any High frequency PCB and high TG PCB projects need production please contact us freely!Email address: [email protected]. BETON PCBs factory focus on High frequency PCB and High TG PCB for over 13 years, and we have strict quality control process for High frequency PCB and high TG PCB manufacturing, so choose BETON PCBs factory for High frequency PCB and High TG will makes your products more competitive with both price and quality.