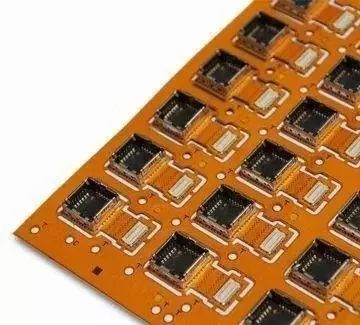

Flexible Printed Circuit (FPC) has the advantages of being soft, light, thin and flexible. With the rapid trend of light, thin, short and small electronic products, it has been widely used in notebook computers, Digital related, mobile phones, LCD monitors, etc.

The traditional FPC board material is mainly based on the three-layer structure of PI film/adhesive/copper foil, and the adhesive is mainly Epoxy/Acrylic, but the heat resistance and dimensional stability of the adhesive are not good, and the long-term use temperature The limit is 100 -200, which makes the field of three-layer flexible copper clad Laminate (3-Layer Flexible Copper Clad Laminate, 3-Layer FCCL) limited. (A) Floating structure of three-layer Flexible board base with glue (B) Structure of two-layer non-adhesive Flexible board FPC base material. The newly developed non-adhesive Flexible board FPC base material (2-Layer FCCL) is only composed of PI film/copper foil , because no adhesive is needed to increase the long-term use dependence and application range of the product.

Important characteristics of non-adhesive soft board FPC substrate

- Heat resistance

The non-adhesive Flexible board FPC substrate has excellent heat resistance because there is no adhesive with heat difference, and the long-term use temperature can reach more than 300 degrees. The relationship between the tear strength of the substrate and the time shows that the tear strength of the non-adhesive flexible board FPC substrate changes very little at high temperature for a long time, while the tear strength of the three-layer glued soft board drops sharply in a short time at high temperature. The relationship between the tear strength of the non-adhesive soft board FPC substrate and the three-layer glued Flexible board substrate and the temperature shows that when the temperature of the non-adhesive Flexible board FPC substrate is greater than 120, the tear strength drops sharply due to the deterioration of the adhesive. Generally, when SMT welding is performed on a flexible board, the temperature is mostly over 300. In addition, the temperature of the pressing process in the production of Rigid-Flex is also as high as 200, which is not suitable for three-layer flexible board substrates. these applications.

- Dimensional stability

The dimensional change of the FPC substrate of the non-adhesive Flexible board is very little affected by the temperature, even at high temperature (under 300°C), the dimensional change rate is still within 0.1%; but the dimensional change rate of the three-layer soft board with glue is greatly affected by the temperature. Good inch stability will be of great help to the thin line process. Today’s high-end electronic products such as LCD, TV (PDP), COF substrates, etc. all emphasize thin line, high density, high dimensional stability, high temperature resistance and Therefore, under the trend of information electronic products gradually moving towards light, thin and short, non-adhesive FPC will become the mainstream of the market.

3.Chemical resistance

The non-adhesive FPC substrate has excellent chemical resistance performance, and the tear strength does not change significantly for a long time, while the three-layer glued FPC substrate has poor chemical resistance due to the adhesive. decreased significantly over time.

Other characteristics of the non-adhesive FPC substrate include reducing the thickness of the substrate, which is in line with the trend of light, thin and short. In addition, because the residual amount of chloride ions after etching is low, the ion mobility is reduced, and the long-term reliability of thin circuits is also reduced.

Manufacturing method of non-adhesive soft board FPC substrate

There are three ways to manufacture FPC substrates for non-adhesive soft boards:

(1) Sputtering method/electroplating method: Using the PI film as the base material, after a metal layer is plated on the PI film by vacuum sputtering, the copper thickness is increased by the electroplating method. The advantage of this method is that it can produce ultra-thin non-adhesive FPC substrates, with a copper thickness of 3 12, and can also produce Flexible boards with different thicknesses on both sides.

(2) Coating method: Using copper foil as the base material, the synthesized polyamic acid is extruded and coated on the rolled copper foil with a precise die head. After drying in an oven and imidization, it forms glue-free Soft board FPC substrate. The coating method is mostly used for single-sided flexible boards. If the copper thickness is less than 12, it is not too late to manufacture and it is difficult to manufacture double-sided flexible board substrates.

(3) Hot pressing method: First coat a thin layer of thermoplastic PI resin with PI film as the base material, first harden at high temperature, and then use high temperature and high pressure to remelt the thermoplastic PI and the thickness of the copper foil is also difficult to be less than 12 . The manufacturing method of FPC base material for non-adhesive Flexible board, among which the [sputtering/plating method] can best meet the ultra-thin requirement – copper foil thickness of 3 12, but at present, it is still necessary to overcome the problems of high equipment investment and technology, in order to achieving mass production goals.

Application and Market Status

According to Beton’s market forecast, in the next 5 years, the non-adhesive FPC base material will gradually replace the three-layer glued FPC base material, the high-end FPC market, taking the Japanese market as an example, the non-adhesive FPC base material The market size has increased from 290,000 square meters in 1997 to 1.72 million square meters in 2000, the market size has grown nearly 6 times, and the market share will also increase from 3.4% to 16.8. In addition, the EU will completely ban the import of products containing halogens and lead and other toxic substances in 2004. Because the adhesive-free FPC base material is exempt from the use of adhesives, it is not necessary to use halogen-containing combustion agents, and at the same time, it can meet the requirements of lead-free. The requirements of high temperature process are the best choice for the industry.

Conclusion: Emphasizing that portable and user-friendly information and communication products have become the mainstream of today’s market, and China has become the world’s second largest notebook computer manufacturer and stimulated by the rapid take-off of the communication market. In the future, portable products will be light and thin. With the trend of short size, high function, thin line and high density, the market demand for ultra-thin non-adhesive FPC substrates with copper thickness below 5 will be very strong in the future.

If you have any PCB demands, please feel free to contact us.

Email:[email protected]

Skype:[email protected]

Telephone number:+86 133 9241 2348

Whatsapp: +86 133 9241 2348