PCBA is the abbreviation of Printed Circuit Board + Assembly, which means that the empty PCB board passes through the SMT assembly, and then goes through the entire manufacturing process of the DIP plug-in, referred to as PCBA.

Printed circuit board, often used in English abbreviation PCB, is an important electronic component, a support for electronic components, and a provider of circuit connections for electronic components. Because it is made using electronic printing technology, it is called a “printed” circuit board.

What does PCBA do

Regarding what PCBA does, let’s learn about it by understanding the role played by PCBA processing equipment:

PCBA processing is an electronic processing industry with a relatively high degree of mechanical equipment integration. The use of more and more mature processing machinery and equipment and the improvement of manufacturing processes have continuously improved the yield and efficiency of PCBA processed products. The processing equipment commonly used in PCBA processing has the following types:

PCBA processing equipment one: printing machine

The printer is located at the front end of the PCBA processing line, and its main purpose is to print solder paste or patch glue on PCB circuit boards. The working process is that after the mesh of the stencil of the printing machine is aligned with the PCB pad, the solder paste or patch glue placed on the stencil is printed on the PCB pad or the corresponding position through the movement of the squeegee for PCBA processing Prepare for component placement in the subsequent process.

PCBA processing equipment two: Glue dispenser

The main purpose of the dispenser is to apply solder paste or patch glue. The working process is to apply a prescribed amount of glue or solder paste on the required position of the PCBA device through the pressure of the vacuum pump. The advantage of the dispenser is that during the production process, there is no need to replace the production jig, which greatly shortens the production cycle, and is suitable for small batch and multi-product production.

PCBA processing equipment three: placement machine

The placement machine is the core mechanical equipment in PCBA processing, also called the placement machine. The main purpose is to accurately remove the known material from the specified location through the pre-set conditions, and correctly mount it to the specified location. The placement and production capacity of PCBA processing mainly depends on the speed and accuracy of the placement machine and other functional parameters. It is also the most technical, complex and expensive equipment in the PCBA process.

The automatic placement machine is a high-speed, high-precision, highly automated, and highly intelligent equipment integrating precision machinery, electric, pneumatic, optics, computers, and sensor technology.

PCBA processing equipment four: reflow soldering machine

The main purpose is to provide a stable and controllable heating environment to fuse the solder pre-distributed by the printer on the PCB circuit board, so that the surface mount component and the PCB pad can be reliably combined with the solder paste.

PCBA processing equipment five: testing equipment

The main function of the inspection equipment is to inspect the assembly quality and street quality of the mounted PCBA. The equipment used mainly includes a magnifying glass, a microscope, an automatic optical detector, an online tester, an X-ray inspection system, and a functional tester. According to the needs of testing, its installation position is the corresponding position behind the production line.

PCBA processing equipment six: rework equipment

The main function of the rework equipment is to rework and repair the PCBA products that have failed to be detected. The tools used are soldering irons, BGA rework stations, etc.

PCBA processing equipment seven: cleaning equipment

The function of the cleaning equipment is to remove the substances that affect the electrical properties of the processed PCBA products or the welding residues that are harmful to the human body, such as flux. If you use no-clean solder, you do not need to clean. The equipment used for cleaning is an ultrasonic cleaner and a special cleaning fluid (washing water: the washing water is a highly volatile flammable liquid, pay attention to safe use).

PCBA interpretation

Exterior

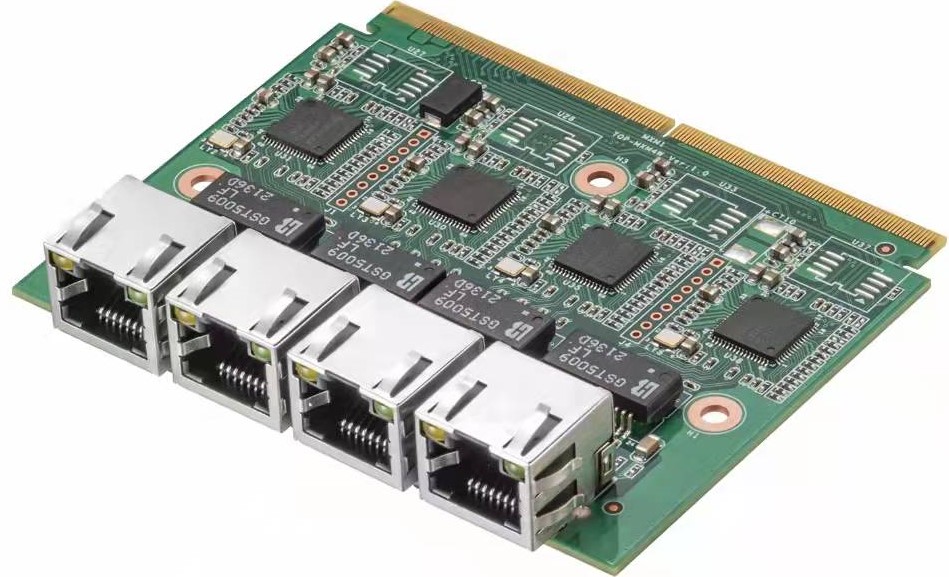

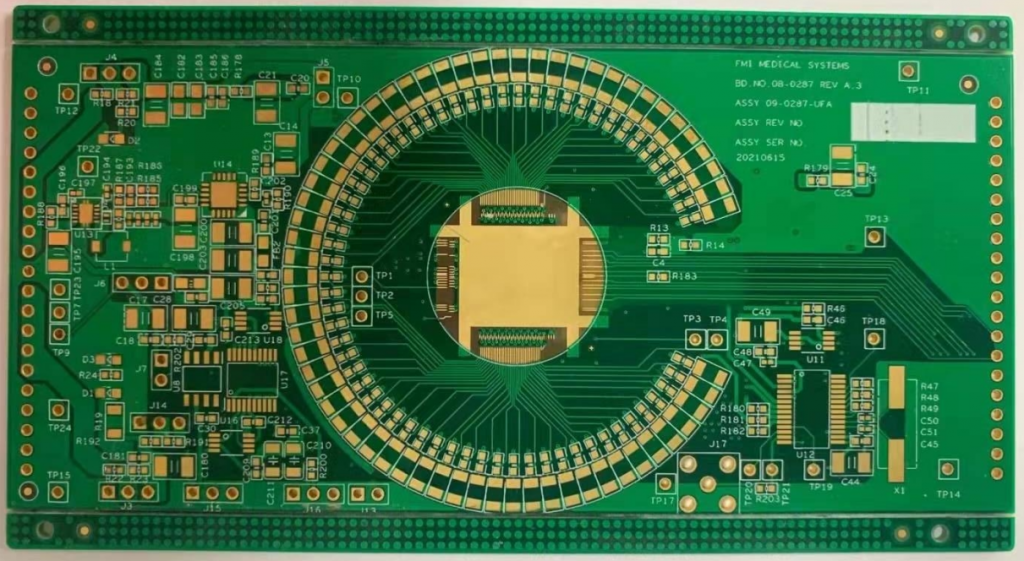

PCBA and PCB look very close, and they are often confused by laymen. In fact, the biggest difference between them is as follows:

The first board with no components is the PCB, commonly known as the optical circuit board! The second board that has been processed and installed with components is called PCBA, commonly known as circuit board. Our most common motherboards and sound cards are commonly known as PCBA in the industry. However, PCBA generally refers to the name used as an accessory in the production process.

Features

The core part of all electronic products is composed of PCBA; the realization of all functions is inseparable from PCBA. Taking a desktop computer as an example, the units inside the chassis do not contain PCBA except for the heat dissipation part, and all the remaining functional units have PCBA. There are PCBA in the hard disk and power supply. The display other than the host has a display driver board (PCBA) and an LCD screen, and there is also a PCBA inside the LCD screen. There is also a small PCBA in the mouse, keyboard, and even the Bluetooth receiver of the wireless mouse and keyboard. Therefore, PCBA is the basic unit of all functions in the electronics industry.

Status

PCBA is the most important part of all electronic product components, similar to the neural network of the human body. The brain of electronic products: CPU is installed on PCBA. The lifespan, operating speed, reliability and stability of general consumer electronic products have the most direct relationship with PCBA. Therefore, the quality of PCBA is also the most direct determinant of the overall quality of electronic products.

If you have any PCB demands, please feel free to contact us.

Email:[email protected]

Skype:[email protected]

Telephone number:+86 133 9241 2348

Whatsapp: +86 133 9241 2348